If you're just getting into laser cutting or engraving, you've probably asked:

“What’s the difference between CO₂, fiber, and diode lasers—and which one do I need?”

Each laser type has its strengths and limitations. Choosing the right one depends on:

- The materials you want to work with

- Your budget and space

- Whether you're doing hobby projects or business production

This guide breaks down how each laser type works, what it's best for, and how to choose the right machine for your needs.

1️⃣ Diode Lasers – Compact, Affordable, and Great for Beginners

Best for: Hobbyists, crafters, engraving wood & coated materials

How It Works:

- Uses a blue (typically 450nm) diode laser module

- Emits visible light that is absorbed by darker or organic materials

Pros:

- Inexpensive and beginner-friendly

- Portable and compact

- Good for engraving wood, leather, paper, dark acrylic, painted metal

Cons:

- Can’t cut transparent materials like clear acrylic

- Weak for bare metal (requires spray or coating)

- Limited cutting power (typically 5–20W)

💡 Great for makers creating signs, coasters, ornaments, and small custom gifts.

2️⃣ CO₂ Lasers – Powerful, Versatile for Cutting & Engraving

Best for: DIY creators, small businesses, cutting acrylic, wood, leather, and engraving glass

How It Works:

- Generates an invisible 10,600nm infrared laser using a gas-filled glass tube

- Excellent absorption in most organic and polymer materials

Pros:

- Cuts and engraves wood, acrylic, leather, glass, fabric, rubber, paper, and more

- Great for making sellable products and layered crafts

- Faster and cleaner cuts compared to diode lasers

Cons:

- Larger and more expensive than diode lasers

- Requires external water cooling and ventilation

- Doesn’t engrave bare metal (unless coated)

💡 Ideal for cutting signs, ornaments, product packaging, home decor, and crafts.

3️⃣ Fiber Lasers – Industrial Power for Engraving Metals

Best for: Metal engraving, jewelry marking, serial numbers, industrial use

How It Works:

- Uses a laser beam amplified through fiber-optic cables

- Wavelength is around 1064nm – absorbed efficiently by metal

Pros:

- Can engrave and mark bare metals: stainless steel, aluminum, titanium, brass

- No need for sprays or coatings

- Precise, fast, permanent markings

- Works well for barcodes, logos, jewelry, tools

Cons:

- Expensive – often $3,000+ USD

- Not suitable for cutting or engraving wood, plastic, or glass

- Designed for engraving, not cutting

💡 Perfect for metal-focused businesses or high-precision branding.

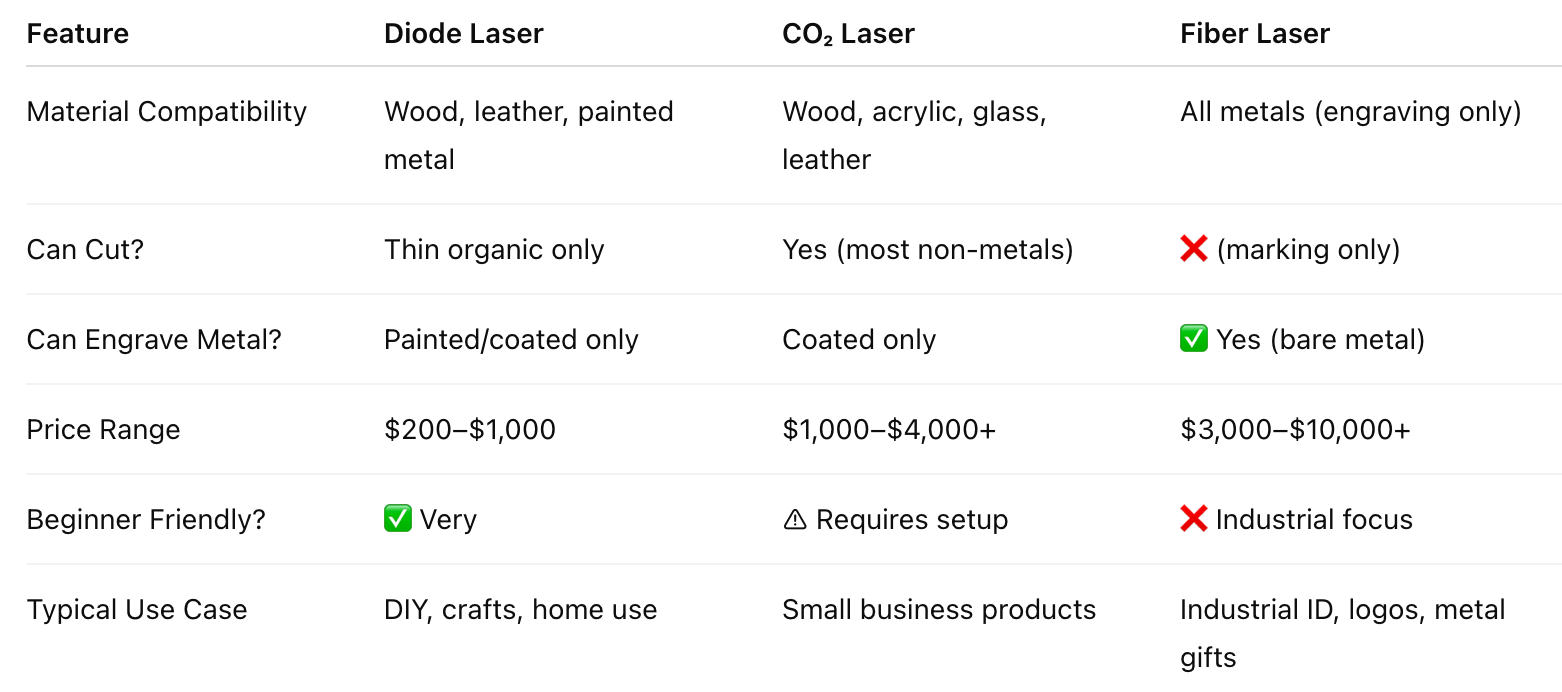

4️⃣ Quick Comparison Chart

5️⃣ How to Choose the Right Laser for You

Ask yourself:

1. What materials do I want to work with?

- Wood, acrylic, and leather → CO₂

- Just engraving metal → Fiber

- Simple engraving or starter projects → Diode

2. Do I need to cut or only engrave?

- Diode = engraving mostly

- CO₂ = cutting and engraving

- Fiber = engraving only

3. What’s my budget?

- Diode: Great entry point

- CO₂: Balanced for serious hobby or business

- Fiber: High-end, ROI-focused investment

FAQs

Q: Can I engrave stainless steel with a diode laser?

A: Only if it’s coated or painted. You’ll need spray (like LaserBond) for marking bare metal.

Q: Can a CO₂ laser engrave glass?

A: Yes! It won’t cut glass, but it can frost or etch designs with proper settings.

Q: Can a fiber laser cut metal sheets?

A: No. Desktop fiber lasers mark the surface but can’t cut through. Cutting requires a dedicated high-power CNC fiber cutter.

Conclusion

Each laser type serves a different purpose:

✅ Diode: Great for beginners, creative hobbyists, and light engraving

✅ CO₂: Best for all-around makers, crafters, and product designers

✅ Fiber: Powerful tool for metal marking, engraving, and industrial needs

✨ Still unsure? Explore real projects made with all three laser types in the Atomm Community, where makers share their settings, results, and creative applications.