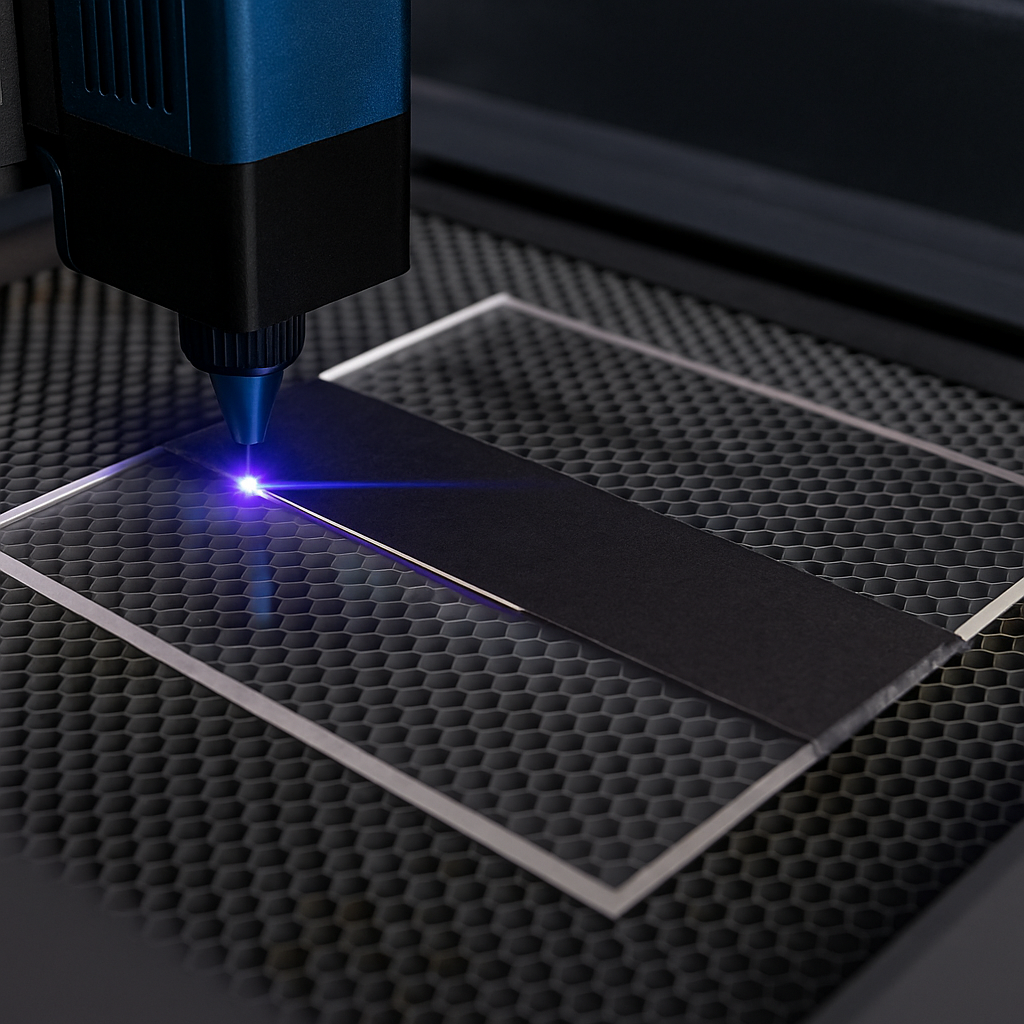

Cutting clear acrylic with a diode laser can be tricky. While diode lasers are perfect for engraving and cutting wood, leather, and dark-colored acrylic, transparent acrylic doesn’t absorb the laser’s wavelength efficiently.

The result? Your laser may pass right through the material without cutting, or you’ll end up with messy, melted edges.

Fortunately, with the right preparation, settings, and techniques, you can achieve clean and successful cuts on clear acrylic using a diode laser. This guide will show you how.

1️⃣ Why Clear Acrylic Is Challenging for Diode Lasers

Unlike dark or opaque materials, clear acrylic lets most laser light pass through. Since a diode laser emits visible light (usually around 450nm blue), the acrylic hardly absorbs the energy.

Common issues include:

- Cuts don’t go through completely

- Edges melt or become rough

- Laser reflection can reduce cutting efficiency

💡 This is why diode lasers cut black or opaque acrylic far more easily than clear sheets.

2️⃣ Step-by-Step Guide to Cutting Clear Acrylic

Step 1: Prepare the Material

- Apply black masking tape or matte black spray paint to the cutting surface

- This helps the diode laser absorb energy instead of passing through

- For spray paint, use a removable, water-soluble coating

Step 2: Set Laser Focus and Power

- High power (80–100%) is often needed

- Slow speed and multiple passes produce cleaner cuts than a single slow burn

- Ensure the laser focus is precise—even a small blur can prevent full penetration

Step 3: Use Multiple Passes

- Make 2–5 lighter passes instead of one heavy cut

- Allow brief pauses between passes to avoid overheating and edge melting

Step 4: Ensure Proper Ventilation

- Acrylic fumes can be unpleasant and potentially harmful

- Always run your air assist or exhaust fan while cutting

3️⃣ Extra Tips for Better Results

- Choose cast acrylic over extruded acrylic, cast acrylic cuts cleaner and polishes better

- Elevate the acrylic sheet slightly. Prevents back reflections and heat marks

- Use a fan or light misting of water on the cut path. Helps minimize melting and improves edge clarity

- Test scrap pieces first. Adjust speed, power, and pass count before committing to your final project

4️⃣ When to Consider a CO₂ Laser

While diode lasers can cut clear acrylic with the right preparation, a CO₂ laser will produce:

- Faster, cleaner cuts with polished edges

- No need for masking or painting

- Capability for thicker acrylic sheets (3–10mm+)

If you plan to produce clear acrylic projects regularly—like LED signs, awards, or layered décor—a CO₂ laser may save time and improve quality.

Conclusion

Cutting clear acrylic with a diode laser is challenging but possible if you:

- Mask the material with tape or matte paint

- Use high power, slow speed, and multiple passes

- Keep the surface clean, ventilated, and well-prepared

With patience and testing, you can create clean edges and professional-looking projects—from custom keychains and ornaments to small light panels and DIY décor.

✨ Want more acrylic cutting inspiration? Visit the Atomm Community to see real maker projects and learn from other laser enthusiasts.