Laser cutting acrylic is a precise process that uses focused beams to vaporize or melt material along programmed paths. This creates clean cuts with smooth edges. Affordable desktop machines are now available for workshops and studios. This gives makers and DIY crafters the ability to produce professional-quality acrylic projects from home. With user-friendly design software and modern CO₂ or diode laser systems, you can easily turn flat acrylic sheets into custom signs, jewelry, models, and many other items with great accuracy. In this guide, you will learn how laser cutting acrylic works, how to choose the right equipment and materials, essential techniques, and inspiring project ideas that highlight acrylic's creative potential.

Why Choose Laser Cutting for Acrylic

Acrylic, also called plexiglass, is a flexible plastic known for its clarity and strength. Laser cutting acrylic has benefits that traditional methods can’t provide. Focused beams create smooth, flame-finished edges. This removes the need for sanding or buffing and saves hours of work while achieving clear transparency. Precision technology allows for detailed designs as fine as 0.1mm, from delicate patterns to complex shapes. The non-contact process ensures clean cuts without chipping or cracking, consistent results over different production runs, and no wear on the tools. With thicknesses ranging from 1mm sheets to 25mm slabs, laser cutting offers great flexibility for custom work, prototypes, and creative DIY projects.

Acrylic, also called plexiglass, is a flexible plastic known for its clarity and strength. Laser cutting acrylic has benefits that traditional methods can’t provide. Focused beams create smooth, flame-finished edges. This removes the need for sanding or buffing and saves hours of work while achieving clear transparency. Precision technology allows for detailed designs as fine as 0.1mm, from delicate patterns to complex shapes. The non-contact process ensures clean cuts without chipping or cracking, consistent results over different production runs, and no wear on the tools. With thicknesses ranging from 1mm sheets to 25mm slabs, laser cutting offers great flexibility for custom work, prototypes, and creative DIY projects.

How Laser Cutting Acrylic Works

Laser cutting acrylic uses a focused beam of light to deliver thermal energy to a specific point on the material surface. CO2 lasers emit infrared light at a wavelength of 10.6 microns, which is especially effective for acrylic. This wavelength is easily absorbed by the material's structure, causing rapid heating that vaporizes the acrylic along the cutting path.

The process starts with your design file, usually created in vector graphics software like xTool Studio. You then import this file into laser control software. The software translates your design into movement commands for the laser head. It controls both the cutting path and important settings like power output, cutting speed, and focal distance.

As the laser beam goes through focusing optics, it narrows down to a spot diameter of about 0.1 to 0.2 mm. This creates an extremely narrow cut width that keeps design details intact. When the focused energy hits the acrylic surface, temperatures shoot up above 160°C, which is the decomposition threshold for acrylic. This causes the material to vaporize and be expelled from the cut area as gas and fine particles. As the laser cuts through the acrylic, the intense heat briefly melts the material before vaporizing it. This results in the polished, flame-finished edge that makes laser-cut acrylic easily recognizable.

Which Types of Acrylic Can a Laser Machine Deal With

Laser cutters work well with different acrylic types, each offering unique traits for your creative projects. Knowing these acrylic material options helps you choose the right substrate for any application:

- Cast Acrylic: This is the top choice for laser cutting. It provides exceptionally smooth, clear edges with minimal frosting. The manufacturing process creates a dense molecular structure that responds well to laser energy, making it ideal for display pieces, awards, and high-end signs where edge clarity is crucial.

- Extruded Acrylic: More affordable and readily available, extruded acrylic cuts reliably but results in slightly more frosted edges compared to cast acrylic. It’s suitable for prototyping, architectural models, and projects where budget concerns are more important than optical clarity.

- Colored and Translucent Acrylics: From bright opaque colors to subtle tints and fluorescent options, pigmented acrylics cut just as effectively as clear varieties. This opens up many creative possibilities for layered designs and decorative uses.

- Mirrored Acrylic: This type has a reflective backing that remains intact when cut from the correct side. It creates beautiful metallic-finished projects without the weight of glass mirrors.

How Thick Can Acrylic Be Cut with a Laser?

The thickness of acrylic that a laser can cut mainly depends on its wattage and technology. For CO2 lasers, a common rule is about 10 watts of power for each millimeter of thickness for a clean cut in one pass. Desktop CO2 lasers (40W to 60W) can typically handle thicknesses of 6 mm to 20 mm. Industrial machines with 150W or more can cut sheets as thick as 25 mm to 50 mm (1 to 2 inches).

Diode lasers have more limitations, usually cutting through 3 mm to 15 mm of opaque acrylic. They typically cannot cut clear or transparent acrylic because the material does not absorb the specific wavelength of the diode.

To get high-quality results on thicker materials, make necessary technical adjustments. A long-focus lens (4 or 5 inches) helps maintain a narrow beam through the depth of the material. The laser should be focused in the center of the sheet instead of just on the surface. To achieve a "flame-polished" clear edge, use low air assist pressure. High pressure can lead to a cloudy or frosted finish.

5 Creative & Inspiring Acrylic Laser Cutting Project Ideas

✨ Looking for inspiration to start your next design? Acrylic is a versatile material that works well with laser cutting. It offers crisp edges, bright colors, and endless creative opportunities. From décor to personalized gifts, the options are wide open. To ignite your imagination, we’ve gathered 5 creative acrylic laser cutting project ideas. Also, you can find more laser cutting acrylic projects in Atomm.

1. Personalized Acrylic Earrings

Elevate your daily style with these beautiful Acrylic Flower Earrings. They blend modern fashion with nature-inspired design. Made from lightweight, high-quality acrylic, these earrings provide all-day comfort and durability. The delicate floral shape adds a striking yet feminine touch to any outfit, making them perfect for both casual brunches and elegant evenings. Available in various colors, these laser-cut floral earrings bring a fresh botanical vibe to your jewelry collection. Treat yourself or give them as a thoughtful gift.

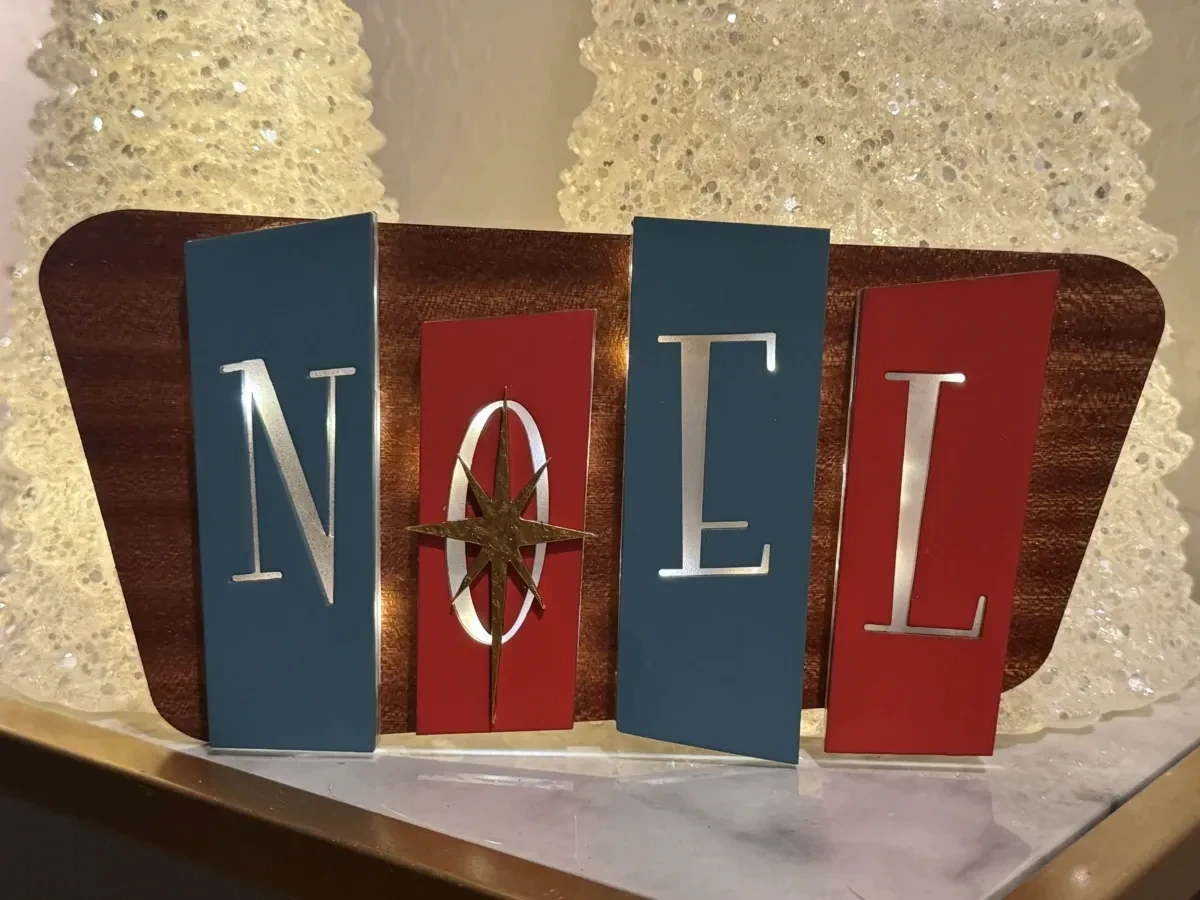

2. Event & Business Signage

Bring a touch of the stylish 1950s to your holiday decor with this Mid-Century Modern Back-Lit Noel Sign. Inspired by the atomic age, this retro piece features sleek typography and a warm, glowing halo effect, creating a festive atmosphere. Ideal for mantels, entryways, or business displays, this light-up sign combines vintage charm with modern LED technology. The layered design adds depth and warmth, ensuring your Christmas decorations stand out. Make your season merry and bright with this timeless piece that captures mid-century winter wonderland charm.

3. Layered Wall Art & Decor

Transform your living space with the Colorful Abstract Geometric Wall Clock. This striking timepiece features a multi-layered design of overlapping geometric shapes and a vibrant color palette, bringing dynamic energy to any room. More than just a clock, it becomes a stunning focal point for home offices, studios, or living rooms. The 3D architectural depth and bold style make it perfect for fans of maximalist and contemporary design. Keep time in style with this unique wall art that merges precise engineering with artistic expression.

4. Personalized Keychains

Carry the relaxed vibes of summer with you everywhere using this Palm Tree Keychain. This compact accessory adds a touch of tropical flair to your keys, backpack, or purse. Made from strong materials to withstand everyday use, it keeps your keys organized while showing off your love for the coast. The clean, recognizable shape makes it a great choice for personalized gifts, party favors, or stocking stuffers. With this stylish and practical accessory, dreamy beaches and ocean breezes are never far away.

5. Custom Night Light (Clear Acrylic)

Light up a child's world with this Custom Clear Acrylic Night Light. It's the ultimate personalized gift for nurseries and bedrooms. Using edge-lit LED technology, the precision-engraved design appears to float in the dark, providing a soft, comforting glow that helps ease bedtime fears. This project allows you to create unique designs, from names to favorite characters, making it a special keepsake for your niece, nephew, or child. Safe, energy-efficient, and durable, this custom lamp adds a warm and professional touch to any room. Give the gift of sweet dreams with a night light that blends creativity and function.

What's the Best Type of Laser Cutter for Acrylic?

CO2 lasers are the best choice for cutting acrylic. They provide unmatched edge quality and cutting efficiency that diode lasers cannot match. The 10.6-micron infrared wavelength from CO2 tubes works perfectly with acrylic’s structure, creating beautifully polished, flame-finished edges. For serious makers, a 40-60W CO2 laser is ideal, providing enough power to cut up to 10mm acrylic reliably while maintaining speed and edge clarity.

While diode lasers are gaining popularity for their compact size and cost-effectiveness, they face significant challenges with acrylic. Their blue light wavelength (usually 450nm) is not well absorbed by transparent and light-colored acrylics. This results in slower cutting speeds and difficulties achieving clean cuts on materials thicker than 3-5mm. However, diode systems are great for engraving acrylic surfaces and can handle thin sheets, making them useful for projects that focus on surface detail.

How to Laser Cut Acrylic Easily

Step 1: Prepare Your Design and Material

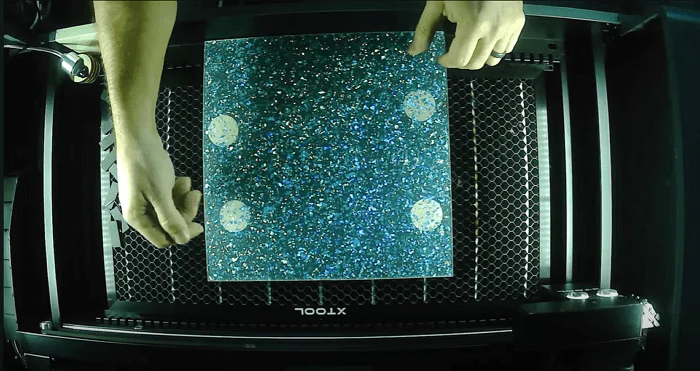

Create vector artwork with hairline stroke paths in SVG or DXF format. Ensure all cutting lines are closed and joined properly. Position your acrylic sheet flat on the cutting bed with protective masking intact to shield surfaces from smoke residue while cutting. Secure the corners with masking tape or magnetic hold-downs to prevent shifting during operation.

Step 2: Dial In Your Focal Point

Adjust the laser head height so the beam focuses precisely on the material surface or 1-2mm into the thickness. This step is crucial for edge quality. Use your machine's focusing gauge or the reliable "business card method" for accuracy, which can make the difference between decent cuts and excellent ones.

Step 3: Configure Optimal Cutting Parameters

Input settings based on your material thickness and laser wattage. For 3mm cast acrylic on a 50W CO2 system, start with 20mm/s speed at 75% power. Always perform a test cut on scrap material first. Getting the perfect parameters takes minutes and saves hours of rework.

Step 4: Execute with Proper Ventilation

Turn on your exhaust system before starting, as acrylic produces fumes that need immediate extraction. Monitor the first few seconds of cutting to check penetration depth and edge clarity, making real-time adjustments if necessary.

Step 5: Clean and Reveal Your Results

Once cutting is complete and the material cools for 30-60 seconds, remove pieces and peel off the protective masking. A quick wipe with isopropyl alcohol removes any minor residue, revealing those stunning flame-polished edges.

Tips for Perfect Acrylic Laser Cutting

These tested tips address common challenges and strategies for achieving flawless edges, precise dimensions, and great visual clarity.

Remove Masking Before Engraving

Peel off protective paper or film from the acrylic before engraving. Engraving through the mask causes it to melt into the design, leaving a gummy residue and a dirty-looking frost instead of a clean finish.

Use Low Air Assist for Engraving

When engraving, use very low air assist—just a little air to keep the lens clean. Too much air blows vaporized plastic back onto the surface, creating cloudy or streaky patches.

Control Power & Speed for a Soft Frost

Aim for moderate power with higher speed (e.g., 40-55% power at 800-1200 mm/s, depending on the machine) to achieve a smooth, frosted white finish. High power or slow speed can create deep, rough grooves instead of fine frost.

Optimize DPI / LPI (Line Spacing)

For frosted engraving, start with a DPI (Dots Per Inch) or LPI (Lines Per Inch) setting around 300-350. A low setting leaves visible scan lines, while a high setting increases job time and heat buildup without improving quality.

Back Engrave for Clear Acrylic (Mirror Design)

For professional edge-lit signs or displays, engrave the back side of the acrylic using a mirrored design. This keeps the front surface smooth and glossy, creating a high-end "floating" image effect when lit.

Adjust Air Assist for Cutting to Avoid Ripples

Use more air for cutting than for engraving, but avoid blasting it to the maximum. Excessive air can cause ripples and stripes on the cut edge. Aim for a smooth, glassy finish by finding a reliable setting that cuts cleanly in a single pass.

Differentiate Acrylic from Wood Processing

Acrylic melts while wood chars. For acrylic, focus on controlling melting and haze with proper air and power settings. For wood, use masking tape, higher air assist, and post-processing like sanding to prevent and remove burn marks.

Test Continuously and Learn from Pros

There are no one-size-fits-all settings. Create and label test cards with different speed, power, and DPI combinations for your specific material and machine. Save them for future reference and consider learning from proven workflows of professional makers.

Laser Cutting Acrylic FAQs: Common Questions Answered

1. How to clean acrylic after laser engraving?

Use a soft microfiber cloth with mild soap and water. Avoid harsh solvents. Gently wipe away residue and fingerprints, then dry with a clean, lint-free cloth.

2. How to tell if acrylic is laserable?

Check the material description for “cast acrylic” or “PMMA.” Avoid PVC or unknown plastics. When unsure, ask your supplier or run a small test away from your main design.

3. Can you laser cut plexiglass?

Yes, plexiglass is a brand name for acrylic (PMMA). It can be laser cut and engraved just like other acrylic sheets, as long as you use a CO₂ laser and set it up properly.

4. How do I achieve clean engravings on plexiglass using laser technology?

Remove the masking, use low air assist, dial in moderate power at higher speed, set DPI around 300–350, and run tests until you get an even frosted effect without deep grooves.

Begin Your Acrylic Laser Cutting Adventure with Atomm

Your journey with laser cutting acrylic starts here. With the techniques and ideas from this guide, you can turn simple acrylic sheets into extraordinary pieces that reflect your artistic vision.

Whether you’re making your first custom keychain, crafting elegant jewelry that catches the light, or designing stunning displays for your home, laser cutting acrylic gives you the right mix of precision and creative freedom. Those beautiful flame-polished edges and detailed designs add a professional touch to every project.

The Atomm community supports makers at all levels. Don’t wait for the perfect moment. Grab some colorful acrylic, start your machine, and let your imagination lead the way. Each piece you create builds confidence and brings the satisfaction of handmade work. Your acrylic laser cutting journey begins today, and we can’t wait to see the beautiful creations you’ll make!