Metal doesn’t need to be complicated or industrial anymore. With metal laser cutting, creators can easily transform basic metal sheets into custom signs, jewelry, home décor, and functional parts. Unlike noisy tools that leave rough edges, laser cutters use focused light to make clean, precise cuts and intricate details. As these machines become more available, more people are discovering how enjoyable and creative working with metal can be. In this guide, we’ll explain how metal laser cutting works, which materials you can use, and how to achieve the best results for your projects.

Can Metal Be Cut with a Laser?

Absolutely! Metal laser cutting is not only possible; it’s also one of the most exciting tools in the modern maker's toolkit. When a high-powered laser beam hits metal, the concentrated energy either melts or vaporizes the material along your design path, creating clean, precise cuts that outshine traditional metalworking tools. However, not every laser can cut metal. Your everyday diode laser won’t work, but fiber lasers and powerful CO2 systems handle metal beautifully. With the right equipment and settings, you’ll be amazed at what you can create, from delicate jewelry pieces to durable industrial parts.Metal doesn’t have to be complicated or industrial anymore. With metal laser cutting, creators can turn plain metal sheets into custom signs, jewelry, home décor, and practical parts with surprising ease. Instead of noisy tools and rough edges, laser cutters use focused light to make clean, precise cuts and fine details. As laser machines become more accessible, more people are discovering how enjoyable and creative working with metal can be. In this guide, we’ll walk through how metal laser cutting works, what materials you can use, and how to get the best results for your projects.

How Does Metal Laser Cutting Work?

Let’s break down the process behind metal laser cutting in simple terms.

The Laser Beam Generation

Your machine produces an incredibly focused beam of light energy, like concentrating sunlight through a magnifying glass but much more powerful. This beam narrows to a tiny point, often smaller than a human hair.

The Cutting Action

When this concentrated energy hits your metal, it heats that spot to extremely high temperatures. The metal melts almost instantly, and a stream of assist gas, such as oxygen, nitrogen, or compressed air, blows away the molten material to create a narrow cutting path called the kerf. It’s like using a blowtorch with robotic precision.

The Digital Control

Your computer controls the entire process. You design your project in software, and the machine translates those vectors into precise movements. The laser head follows your design while adjusting power and speed based on your metal type and thickness.

The beauty of laser cut metalwork is its ability to handle complexity. Sharp corners? No problem. Intricate curves? Easy. Details that would take hours with traditional tools are accomplished in minutes, giving you more time to explore your next creative idea.

Which Types of Metal Can a Laser Machine Cut?

Your laser cutter can manage a wide range of metals, each with unique qualities for your projects. Let’s look at what works best.

- Stainless steel is a favorite for laser cutting. It cuts cleanly, resists corrosion, and offers beautiful edge quality, making it perfect for everything from kitchen art to outdoor sculptures.

- Mild steel (carbon steel) is an economical option. It cuts efficiently and works well for structural projects, brackets, and functional parts.

- Aluminum requires more power because of its reflective surface, but modern fiber lasers handle it well. It’s great for lightweight components and decorative pieces.

- Copper and brass add warmth to your laser cut metal designs. Although they need higher power settings due to their reflectivity, the results are stunning for jewelry and artistic applications.

The key is to choose your metal based on your project needs and your machine’s capabilities. Each metal has its own character, and finding what works best for your creative vision is part of the fun!

What Are the Main Parameters for Laser Cutting Metal?

When laser cutting metal, it’s crucial to manage key parameters to ensure clean, accurate, and efficient cuts:

- Laser power: The energy output of the laser, usually measured in watts (W) or kilowatts (kW). Higher power allows cutting through thicker or denser metals.

- Cutting speed: The rate at which the laser head moves across the material. Finding the right speed balances productivity with cut quality.

- Pulse frequency: The number of laser pulses per second, affecting cutting precision, processing speed, and the size of the heat-affected zone (HAZ).

- Focal spot size: The diameter of the laser beam at its focus point. A smaller spot size produces finer kerfs and more precise cuts.

- Assist gas pressure: The pressure of the gas used to blow away molten metal and reduce oxidation. It needs to be adjusted based on the type and thickness of the metal for optimal results.

How Thick of Metal Can a Laser Cutter Cut?

The thickness capacity depends on your laser's power and type—think of it as matching your tool to the task.

Fiber lasers are leaders in metal cutting. A 1kW fiber laser can cut up to 5mm stainless steel, while 3kW systems can manage 12-15mm. With 6kW or more, you can cut 25mm or thicker mild steel. These machines are heavyweights.

CO2 lasers can cut thin metals (typically under 6mm for stainless steel) but really excel with thicker materials when they have high wattage, specifically 4kW+ systems.

Here’s the reality: thicker cuts result in slower speeds and wider kerfs. For metal laser cutting projects, most makers find success with materials between 1-8mm thickness, where cutting speed, edge quality, and material cost are well balanced.

If you’re just starting, focus on materials under 3mm. You’ll achieve faster cuts, cleaner edges, and more room for creative exploration. As your skills improve, you can expand your cutting thickness. That’s the beauty of this technology—it grows with you!

5 Creative & Inspiring Metal Laser Cutting Project Ideas

✨ Looking for inspiration to start your next design? Metal is a powerful material that shines with laser cutting. It offers sleek finishes, durable strength, and striking precision that elevate any project. From functional pieces to artistic creations, the possibilities are bold and limitless. To spark your creativity, we’ve gathered 5 innovative metal laser cutting project ideas. Also, you can find more laser cutting metal projects in Atomm.

1. Handcrafted Metal Rose Sculpture

Capture the beauty of nature that never fades with this Handcrafted Metal Rose laser cutting. It features intricate, lifelike petals and detailed leaves, making it a stunning piece of metal art. This everlasting flower is a perfect romantic gesture for Valentine’s Day or a traditional Iron Anniversary gift (6th year). Unlike fresh flowers, this durable metal sculpture lasts over time, symbolizing enduring love. Whether you display it in a vase or as a standalone centerpiece, this rose adds elegance and craftsmanship to any home decor.

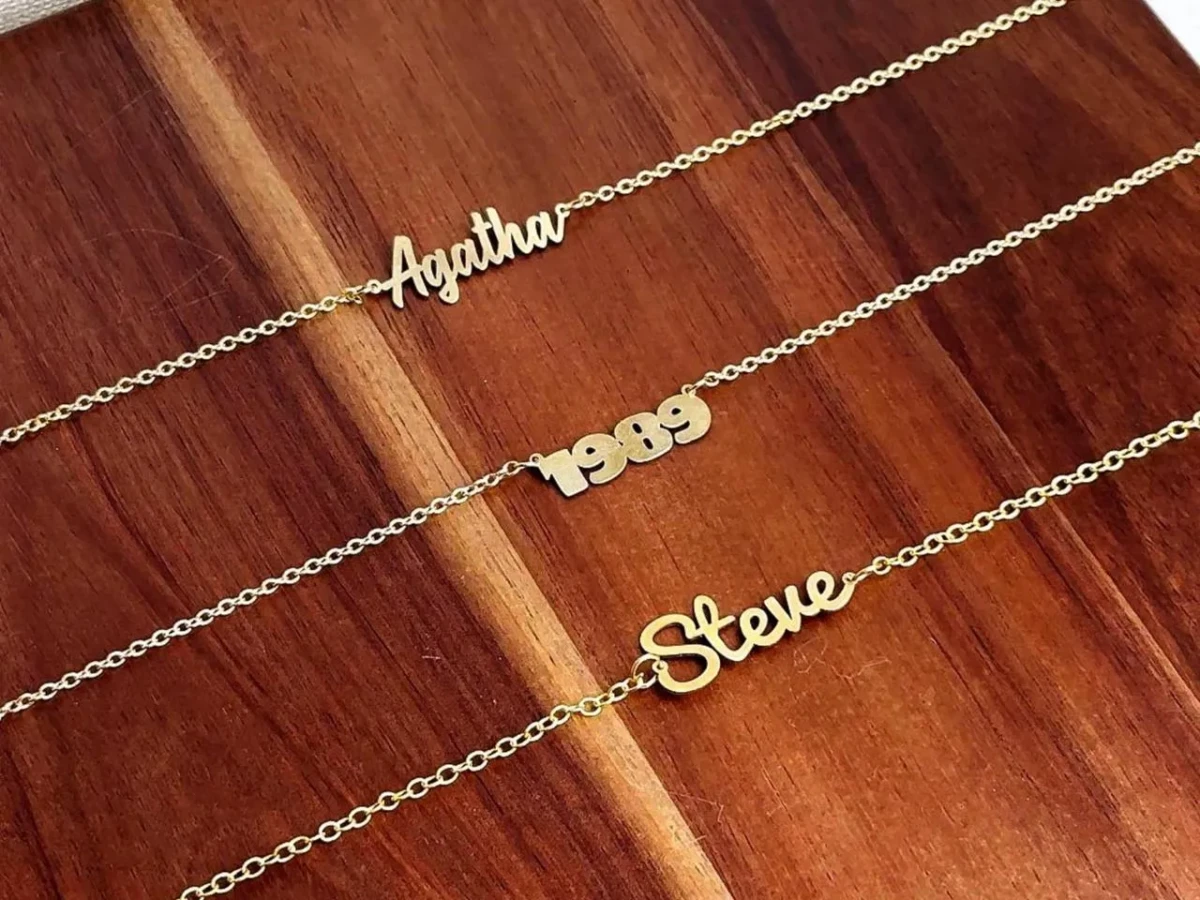

2. Metal Laser Cut Name Necklace

Wear your identity proudly with this custom Metal Name Necklace laser cutting. Precision-cut with laser technology, this piece of personalized jewelry provides a sleek, modern look that goes well with any style. Available in finishes like polished stainless steel, gold tone, or silver, it makes a thoughtful gift for birthdays, bridesmaids, or special occasions. The sturdy metal ensures the script remains crisp and unbending, while the fine detailing highlights the elegance of the chosen typography. Elevate your accessory game with a custom nameplate necklace that is uniquely yours.

3. Stainless Steel Metal Sign Cutting

Upgrade your business branding or home office with this professional Stainless Steel Laser cut Metal Sign. This project shows how laser cutting creates sharp, clean logos and fonts that convey authority and style. Stainless steel offers superior weather resistance and a modern look, making this sign suitable for both indoor lobbies and outdoor facades. Whether you need a sleek house number or a bold corporate logo sign, this durable metal solution gives a high-end finish that resists rust and wear, ensuring your message stays clear for years.

4. Decorative Aluminum Garden Lamp

Brighten your backyard with the enchanting glow of this Decorative Aluminum Garden Lamp. Designed to withstand the elements, this lantern is made from aluminum, ensuring it stays rust-free and lightweight. The intricate cut-out patterns cast beautiful shadows when lit, creating a cozy atmosphere for patios, walkways, or garden beds. This project combines functional outdoor lighting with artistic metalwork, serving as a stunning sculptural piece even during the day. Enhance your landscape with this weather-resistant metal lantern that blends durability with delicate style.

5. Stainless Steel Rocket Stove

Prepare for your next outdoor adventure with this efficient Stainless Steel Rocket Stove. Ideal for campers, hikers, and survivalists, this stove maximizes fuel efficiency while minimizing smoke, allowing you to cook meals using just twigs and small branches. The strong stainless steel construction ensures it handles high heat without warping, and the clever design often enables flat-packing for easy portability. This DIY camping stove project is a must-have for any emergency kit or outdoor setup, offering a reliable, eco-friendly way to cook off the grid.

What's the Best Type of Laser Cutter for Metal?

The answer is clear: fiber lasers are the best choice for metal laser cutting, and the difference is significant. Fiber lasers produce a wavelength that metal absorbs very efficiently, providing faster cuts, cleaner edges, and lower operating costs compared to other technologies. They're the industry standard for a reason, whether you have a small workshop or a production facility. CO2 lasers can cut thin metals with high wattage (around 150W+), but they are generally better for wood, acrylic, and non-metal materials. You'll face higher maintenance and electricity costs for less impressive results on metal. Diode lasers are not suitable for metal cutting. Although some manufacturers claim metal-cutting diode modules exist, they perform slowly and are limited to the thinnest materials. Avoid the hassle.

How to Laser Cut Metal Easily

Starting with metal laser cutting doesn't have to be daunting. Follow this simple workflow, and you'll be creating amazing pieces in no time.

Step 1: Design Your Project

Begin in vector software like Adobe Illustrator, Inkscape, or your laser's design program. Create your design with vector paths; these lines tell your laser where to cut. Keep line weights consistent and remove duplicate paths that waste time and energy.

Step 2: Prepare Your Material

Clean your metal surface thoroughly. Oils, dust, or oxidation can affect cutting quality. Secure your material flat against the cutting bed; warped metal can create focus problems that ruin the edges.

Step 3: Configure Your Settings

This is where the magic happens! Input your material type and thickness into your laser's software. Most modern machines have preset libraries offering great starting points for power, speed, and focus position. If there are no presets, start conservatively and run small test cuts.

Step 4: Run a Test Cut

Always test on scrap material first. A 10mm square can show you if your settings work. Adjust power or speed based on the results.

Step 5: Execute Your Cut

Hit start and watch your laser cut metal design come alive! Keep an eye on the first minute to ensure everything runs smoothly, then let the machine work its precision magic.

Tips for Successful Metal Laser Cutting

When working with metal laser cutting, attention to key factors can make a big difference in achieving accurate, high-quality results:

- Always Test Before Committing: Run small test cuts with new metal or thickness to dial in the right laser power, speed, and gas settings, ensuring precision without wasting material.

- Account for the Kerf: Remember that the laser removes a small amount of material along the cut line. Adjust your design to consider this width to maintain accurate dimensions.

- Optimize Focus and Beam Quality: Ensure the laser is properly focused and the lens is clean. A sharp, well-focused beam produces cleaner cuts, reduces heat damage, and preserves intricate details.

- Choose the Right Assist Gas: Different metals and cutting goals need different gases. Oxygen speeds up cuts and creates bright edges on steel, while nitrogen prevents oxidation for stainless steel and aluminum.

- Balance Speed and Quality: Don’t cut too fast. High speeds may save time but can create rough edges or require more cleanup. Adjust based on the material’s thickness and complexity.

- Plan for Complex Designs: Intricate shapes need careful path planning to avoid burn marks or incomplete cuts. Break designs into segments if needed to maintain precision.

- Maintain Your Machine Regularly: Keep lenses, mirrors, and rails clean and aligned. Regular maintenance ensures consistent performance, a longer machine life, and better cut quality.

- Experiment and Innovate: Don’t hesitate to try new combinations of materials, power settings, or assist gases. Experimentation fuels creativity and helps you discover unique effects and finishes.

Metal Laser Cutting & Engraving FAQs

1.Will a 10W laser cut metal?

Yes, a 10W laser can cut or mark very thin metals like foil-thin steel (around 0.1mm) or thin copper/brass (around 0.2-0.5mm) with several passes, especially if it’s a powerful diode or specific NIR (Near-Infrared) laser. However, it struggles with reflective metals like aluminum and typically only engraves (marks) thicker steel, requiring higher wattage (50W+) and often a fiber laser for more serious metal cutting.

2.Which are the best metal laser cutting machines for 2025?

For 2025, the xTool MetalFab is highly recommended for all-in-one workshops due to its specialized fiber laser precision that handles welding, cutting, and cleaning in a single system. For small businesses or hobbyists needing a desktop option, the xTool F2 Ultra is a top choice, as its 60W MOPA laser efficiently cuts thin metals like 2mm brass and stainless steel while offering high-speed color engraving.

Start Creating Smarter with Metal Laser Cutting

Metal laser cutting helps makers achieve precise results while working faster and more efficiently. By understanding how materials and cutting parameters interact, you can create cleaner cuts, stronger parts, and designs that truly stand out. With Atomm, metal laser cutting becomes even more accessible. From ready-to-use design resources to creative tools, Atomm helps you move quickly from idea to finished piece. Whether you’re prototyping, crafting, or scaling production, Atomm allows you to turn inspiration into reality with confidence. Explore what’s possible and start creating smarter at www.atomm.com.