Laser engraving wood—also commonly searched as wood laser engraving—is one of the most rewarding ways to create custom, meaningful, and profitable products. Whether you're a hobbyist crafting gifts or a small business offering engraved items for sale, mastering wood engraving unlocks huge creative and commercial potential.

In this guide, you'll learn which woods work best, how to set up your laser, what settings to use, and the kinds of projects that consistently impress.

🌲 1. How Laser Engraving on Wood Works

Laser engraving burns or vaporizes the surface of the wood to create marks, patterns, or images. The result depends on your laser type (CO₂ or diode), how you prepare the wood, and what settings you use.

You don't need industrial machines to get clean results—small desktop lasers are fully capable of producing professional-grade engravings if you set them up properly.

🪵 2. Best Types of Wood for Engraving

Some woods engrave much better than others. Here's a breakdown of common options:

- Basswood – Soft and uniform; ideal for photo engraving.

- Birch Plywood – Clean, consistent surface; great for signs and coasters.

- Maple – Dense with light color; delivers sharp contrast.

- Cherry – Richer tone; chars darker, may require masking.

- Walnut – Looks beautiful but engraving shows less contrast.

- Pine – Affordable and rustic; can burn unevenly due to resin.

For the cleanest results, stick to light-colored woods with minimal resin content.

⚙️ 3. Laser Machine Settings for Wood

Settings vary by machine, but here are general guidelines:

- For a 40W–60W CO₂ laser, try 50–70% power with 300–500mm/s speed.

- For a 5W–10W diode laser, use 90–100% power with 100–300mm/s speed.

- Use 300–500 DPI resolution for photo-quality engraving.

Always test your settings on scrap wood before running a final piece.

🧼 4. Preparing Wood for Engraving

Before engraving:

- Sand the surface smooth, especially for photos.

- Apply masking tape to protect the wood and reduce burn marks.

- Make sure your board is flat to avoid focus errors.

- Focus the laser properly—use a guide stick or autofocus if available.

- Preview the design boundaries using your laser software.

🎁 5. Wood Engraving Project Ideas

Here are creative and profitable projects you can make:

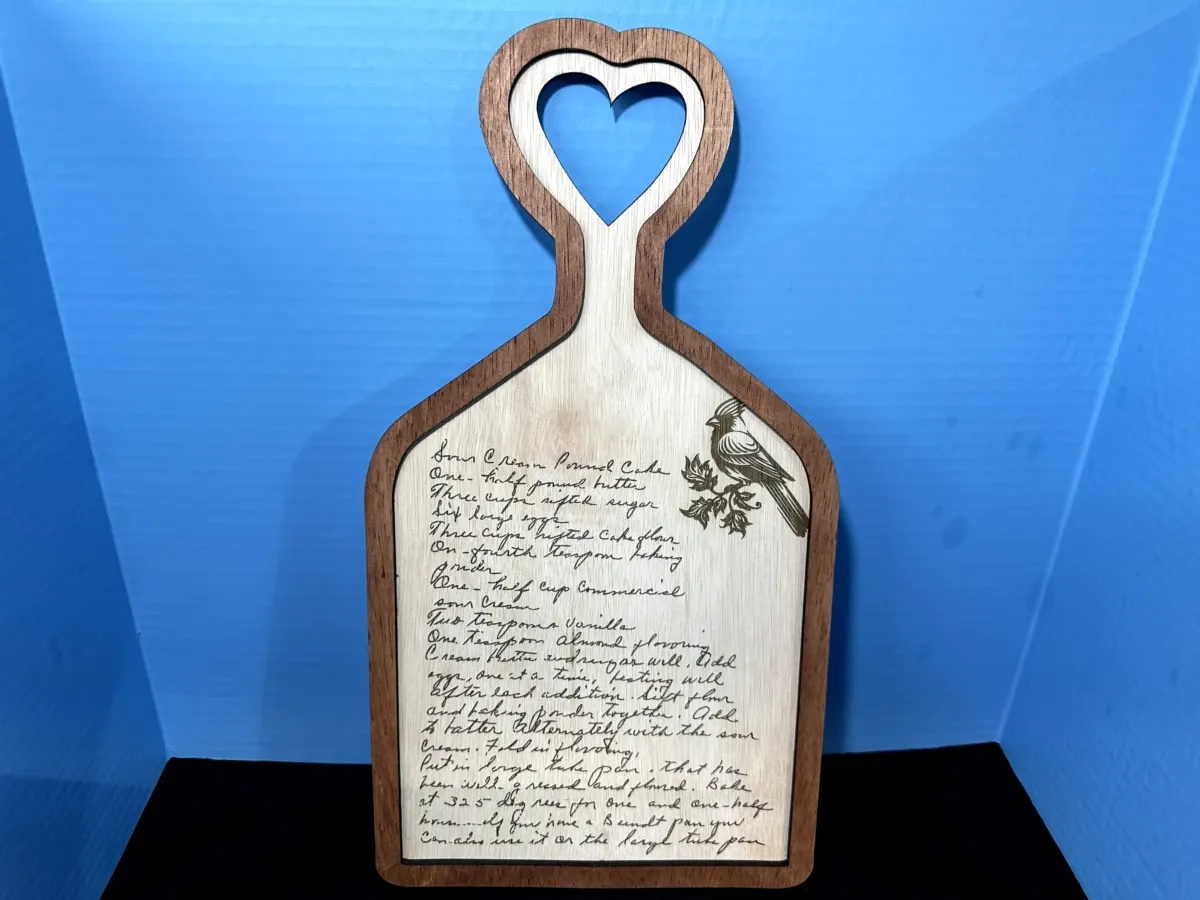

- Customized cutting boards with names or recipes

Explore more cutting board projects and download the files>>

- Coasters with mandala, floral, or geometric designs

Explore more coaster ideas and download the files>>

- Photo plaques using grayscale engraving

Explore more photo frame ideas and download the files>>

Explore more photo frame ideas and download the files>>

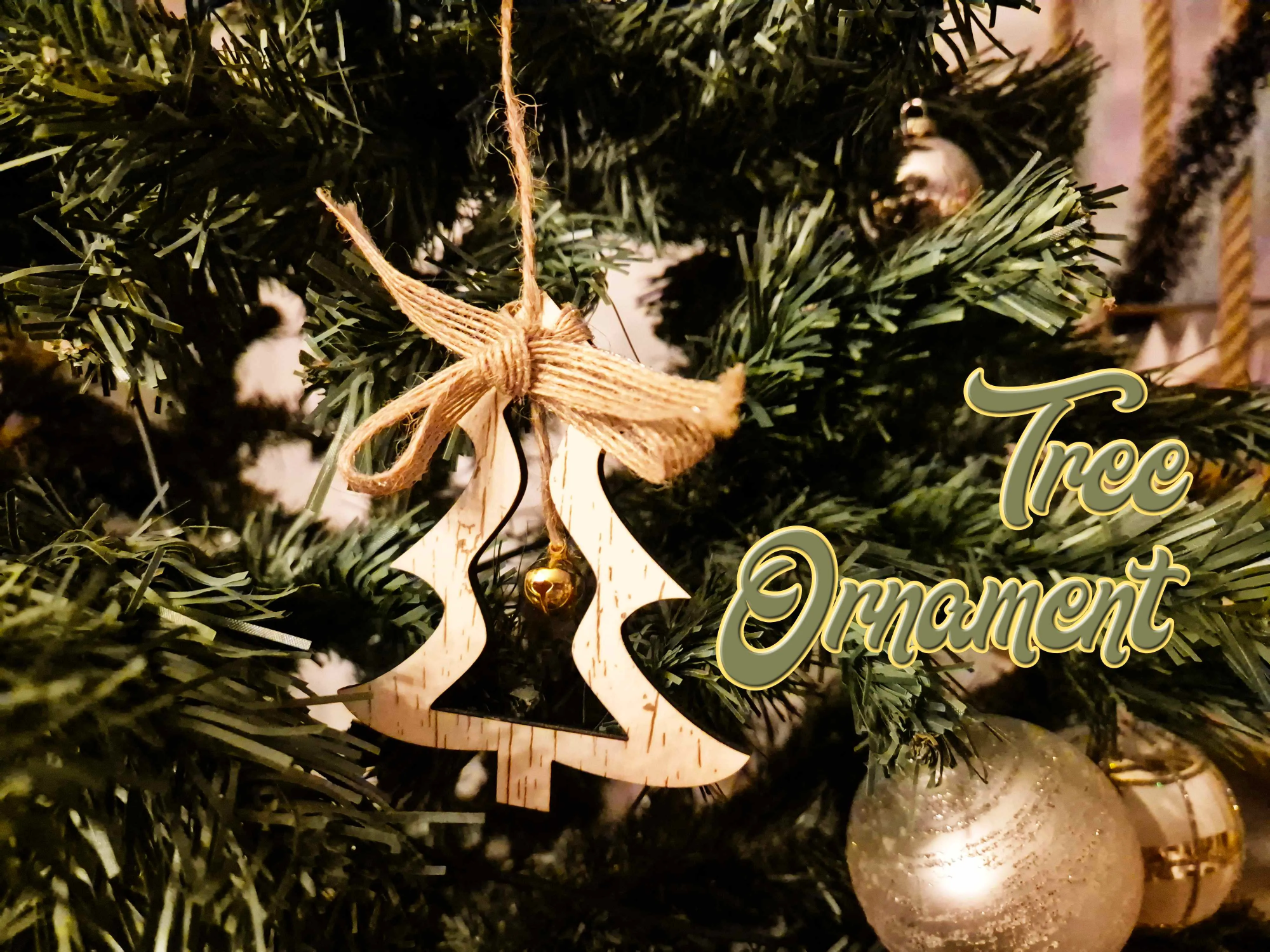

- Holiday ornaments or personalized gift tags

Check more holiday ornament ideas and download the files>>

- Educational flashcards, puzzles, or toys

Explore more game ideas and download the files>>

- Layered art made from plywood or MDF

Explore more layered art ideas and download the files>>

These projects are popular on Etsy, at craft fairs, and for personalized gifting.

💼 6. Selling Laser Engraved Wood Products

To sell successfully:

- Offer personalization (names, initials, dates).

- Create reusable templates for batch production.

- Keep production time low—most items should engrave in under 5 minutes.

- Bundle related products (like coasters and signs) to increase cart value.

Popular places to sell include:

- Etsy, Shopify, and Amazon Handmade

- Local gift stores and farmers markets

- Corporate gifting clients

- School fundraisers or community events

🧩 7. Common Problems & Fixes

Here are frequent wood engraving issues and how to fix them:

- Burn marks or edges too dark – Lower the power or increase the speed; apply masking tape.

- Faded engraving – Increase the power or slow down the speed.

- Uneven result – Make sure your wood is dry and clean; moisture causes irregular burns.

- Smoke residue – Improve exhaust or use air assist.

- Blurry lines – Refocus the laser and ensure the surface is perfectly flat.

❓ FAQ – Laser Engraving Wood

Q: Can I engrave on any wood?

A: Technically yes, but light woods like basswood and maple give better contrast. Avoid resin-heavy woods.

Q: Do I need to seal the engraved area?

A: Not required, but applying a clear finish can protect and enhance the look.

Q: What’s the difference between cutting and engraving?

A: Engraving marks the surface; cutting goes all the way through.

Q: Is laser engraving wood profitable?

A: Yes—many small businesses succeed by offering personalized wood items with low production cost and high perceived value.

✅ Final Thoughts

Wood laser engraving is a versatile and rewarding way to create beautiful and sellable products. With the right preparation, settings, and creativity, you can turn even the most basic piece of wood into something unforgettable.