A CNC laser cutting machine might sound like something built for factories—but today’s compact and affordable models are empowering creators everywhere. Whether you're a DIY maker, small business owner, or tech-savvy designer, CNC laser cutting gives you precision control over materials like wood, acrylic, and leather.

This article explores how CNC laser cutters work, what you can do with them, how to choose the right machine, and how to set it up for creative or commercial success.

🔧 1. What Is a CNC Laser Cutting Machine?

CNC stands for Computer Numerical Control. A CNC laser cutter uses a high-powered laser beam—directed by software instructions—to precisely cut, mark, or engrave flat materials.

Unlike manual tools or blade-based cutters, CNC laser machines work by vaporizing or melting the material in a narrow path, offering cleaner edges and more detailed results. The process is automated, highly repeatable, and perfect for intricate patterns or mass production.

⚙️ 2. How Does It Work?

Here’s what happens when you run a job on a CNC laser machine:

- You create or import a design using CAD or vector software like LightBurn or Illustrator.

- The machine reads those paths and converts them into laser movement instructions.

- The laser beam—generated from CO₂ or fiber optics—hits a lens that focuses it to a tiny point.

- The beam either cuts through or engraves the surface by burning or vaporizing material.

- Fans or air assist blow away smoke and debris for cleaner results.

Most machines let you adjust power, speed, and passes to match your material type and thickness.

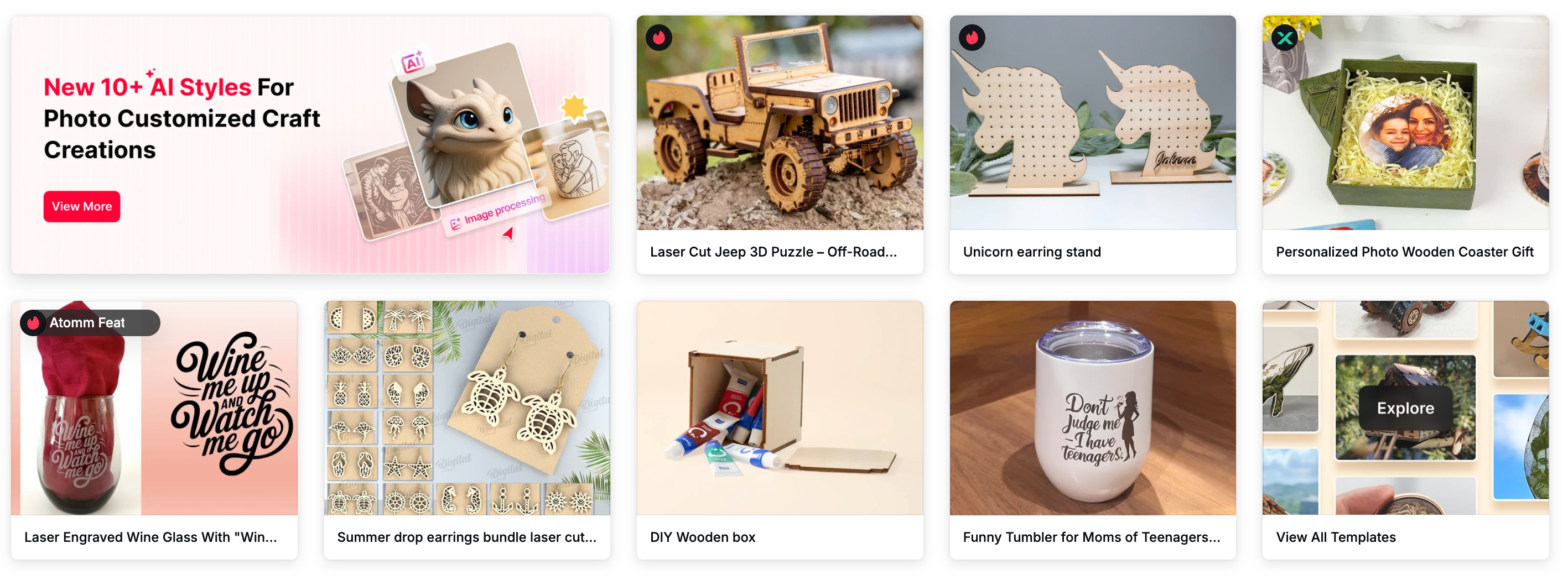

🧪 3. What Can You Make With a CNC Laser Cutter?

CNC laser cutters are incredibly versatile. Here are common use projects:

- Custom signage – Business logos, home wall art, office nameplates

- Gift products – Personalized keychains, bookmarks, cutting boards

- Event décor – Table numbers, ornaments, engraved guest favors

- Layered art – Multilayer mandalas, 3D topographic maps

- Jewelry – Intricate earrings, bangles, charms

- Educational kits – Puzzles, flashcards, STEM build sets

- Packaging prototypes – Cardboard or MDF folded boxes

For small businesses, these projects can easily be sold on platforms like Etsy or offered as custom services locally.

🏗️ 4. Best Materials to Use

Depending on your machine type (CO₂ or fiber), you can cut and engrave materials such as:

- Wood (birch, basswood, MDF, cherry)

- Acrylic / Plexiglass

- Leather and faux leather

- Cardboard and kraft paper

- Fabric and felt

- Anodized aluminum (for engraving only)

- Steel, brass, copper (fiber laser only, high power)

Always check the safety of materials—avoid PVC or vinyl, which emit toxic gas.

🛒 5. How to Choose the Right CNC Laser Cutting Machine

When shopping for your first (or next) CNC laser cutter, consider these factors:

Laser type

- CO₂: Ideal for wood, acrylic, paper, leather

- Fiber: Required for cutting metal

Power level

- 40W–60W CO₂ handles most small business needs

- 100W+ CO₂ for faster production

- 20W–50W Fiber for precision metal work

Working area

- 300x500mm or larger if you do signage or multiple cuts at once

Software compatibility

- Ensure it works with xTool Creative Space, LightBurn, RDWorks, or SVG/DXF export

Add-ons

- Look for air assist, rotary attachment, and honeycomb bed for flexibility

🧰 6. Setting Up Your Machine

Before starting production, make sure to:

- Connect exhaust ventilation to remove smoke

- Level the machine bed and focus the laser

- Test cut on scrap material before running your full project

- Secure your workpiece using clips or magnets

- Use proper safety gear: glasses, airflow, and never leave it unattended

Tip: Start with thin plywood or 3mm acrylic—these are easy to cut and forgiving for beginners.

💼 7. Who Uses CNC Laser Cutters?

- Hobbyists – creating home décor and gifts

- Entrepreneurs – launching online stores, engraving services

- Architects / Designers – prototyping or scale models

- Educators – building STEM or fabrication lab resources

- Marketing teams – producing branded giveaways or signage

Whether you want to sell products or just craft smarter, CNC laser cutters are efficient, fast, and highly scalable.

🚫 8. What to Avoid

Some common mistakes when getting started:

- Running full-speed jobs before test cuts

- Forgetting to align the laser focus

- Cutting unapproved materials (e.g., PVC = toxic fumes!)

- Ignoring ventilation—smoke buildup can damage parts

- Underestimating machine size: always get a larger bed than you think you need

⚔️ CNC Engraving (Cutting) vs Laser Engraving (Cutting): Discover the Difference

Though they often serve similar creative purposes, CNC engraving machines and laser cutters use completely different technologies—and that impacts how they cut, how fast they work, and what materials they handle best.

CNC Engraving (Mechanical):

- Uses rotating bits or mills to carve, gouge, or drill into materials.

- Better for deep cuts, 3D carving, and hard surfaces like aluminum or hardwood.

- Generates dust and noise, needs more mechanical force and maintenance.

- Limited in fine detail or sharp corners due to tool shape.

Laser Engraving (Non-Contact):

- Uses a focused beam of light to vaporize the material.

- Excellent for precise outlines, sharp text, and photo etching.

- Works best on thin sheets, especially wood, acrylic, leather, and paper.

- Requires ventilation to handle smoke but is quieter and easier to automate.

💡 Summary: Use CNC routers for depth and strength. Choose laser engraving for precision, speed, and material versatility.

❓ FAQ – CNC Laser Cutting Machine

Q: Can a CNC laser cut metal?

A: Only fiber lasers or very high-powered CO₂ machines can cut metal effectively. Standard hobby lasers can't.

Q: Is CNC laser cutting safe?

A: Yes, with proper ventilation, goggles, and fire precautions. Never walk away while it’s running.

Q: Do I need special software to run it?

A: Most machines work with xTool Creative Space, LightBurn or RDWorks. You can also export SVG/DXF files from Illustrator, CorelDRAW, or Inkscape.

Q: What’s better: laser or CNC router?

A: Laser is faster and cleaner for thin materials and detail work. Routers are better for deep carving and 3D shaping.

✅ Final Thoughts

A CNC laser cutting machine is no longer just an industrial tool—it’s a creative powerhouse for makers, designers, and small business owners. Whether you’re cutting signage, prototyping packaging, or crafting layered artwork, this tool can turn your ideas into reality with unmatched precision.