![[Laser cut and engrave] Laser Cut Wooden Rose Earrings with Silver Hooks](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0b7d1d1b-ea57-41f5-8374-7d0d60c4d5fe.png?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Rose Earrings with Silver Hooks](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0b7d1d1b-ea57-41f5-8374-7d0d60c4d5fe.png?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Rose Earrings with Silver Hooks](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/cdeb4ab5-a8b4-40f2-90ee-731770182dc0.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

🌹 Rose Wood Cut Earrings | UV vs Blue Light Test

Information

People keep saying UV is a "cold laser", so I really wanted to see how it performs on wood cutting.

This time, I tested UV cutting on 3mm basswood and compared it directly with blue light using my F1 Ultra.

The difference in the final result was pretty obvious, so I figured I’d share the whole process here👀

Instruction

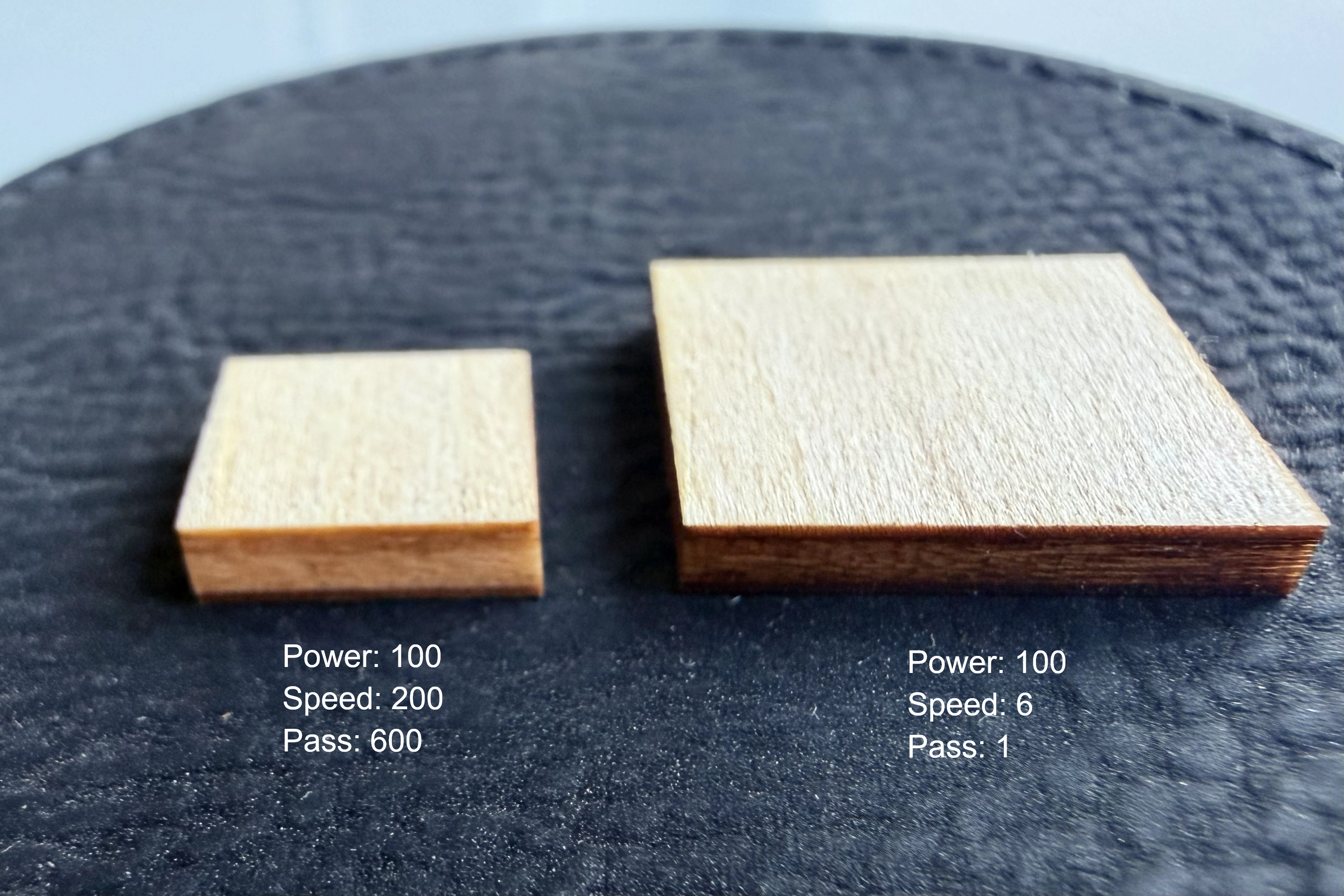

Step1: Testing Wood Cutting with UV

- I started by testing UV cutting on wood. At the beginning, I simply followed the official recommended cutting settings (Power: 100, Speed: 6, Pass: 1) and cut a small square. It did cut through and very fast, but there were still black edges on the wood 😕

- Then I tried another set of parameters shared by other users: Power: 100 Speed: 200 Pass: 600

Yes, 600 passes 😅 It sounds a bit extreme and it did take more time, but the result is very different. No visible burning at all — just the natural wood color and very clean edges.

Step2: Rose Earrings Cutting with UV

Based on this, I used the same “faster speed, more passes” setup to cut a rose shape for earrings 🌹

The result came out really nice. The details were sharp and the surface looked clean.

⚠️One thing worth mentioning: because the UV spot size is very small, the cutting gaps are extremely thin, so removing tiny parts requires some patience.

Step3: Cutting Wood with Blue Light

Next, I switched to blue light on the F1 Ultra 🔵

- I used the recommended blue light parameters from the software: Power: 100,Speed: 20,Pass: 6

This didn’t go very well. Some parts of the rose were heavily burned and carbonized 😬

- I then lowered the power manually to 90%. This time the cut went through, but the edges were still quite dark, especially when compared to the UV result (I stopped testing here. If you’ve got better parameters, I’d love to see them:))

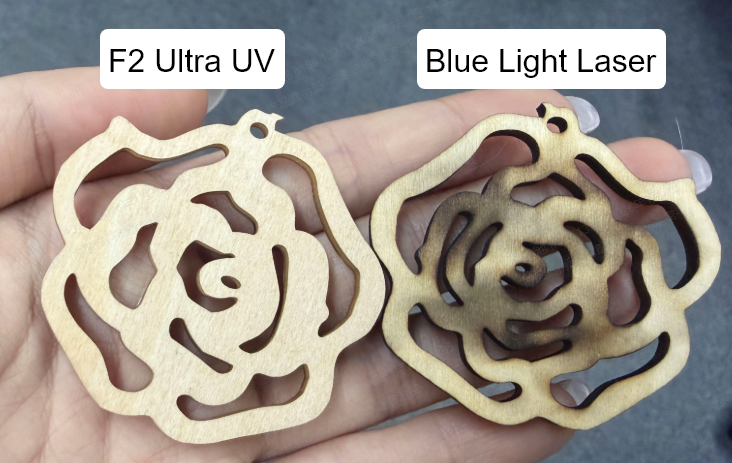

Step4: Comparison

When you put the two results side by side 👀, the difference is pretty clear, especially on the cut edges.

🔵 Blue light: dark, carbonized edges

🟣 UV: clean edges, natural wood color

For this kind of detailed wood jewelry, UV really feels closer to cold processing. Less burning, less cleanup, and a more natural finish overall.

💡This is just my own test and experience, but hopefully it’s helpful if you’re thinking about using UV or blue light for cutting wood:)