![[Laser cut and engrave] Laser-Engraved IKEA RÖRT Utensil Set (Beech Wood) - Sassy Chef](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/26d7fa11-18f0-4f62-8d06-cab535842eac.jpg?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser-Engraved IKEA RÖRT Utensil Set (Beech Wood) - Sassy Chef](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/26d7fa11-18f0-4f62-8d06-cab535842eac.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser-Engraved IKEA RÖRT Utensil Set (Beech Wood) - Sassy Chef](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0a2e1249-d1c5-4524-a206-ff6527f27b75.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser-Engraved IKEA RÖRT Utensil Set (Beech Wood) - Sassy Chef](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/ac45a3cd-b586-4702-8ecf-8ddfa7eb950b.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

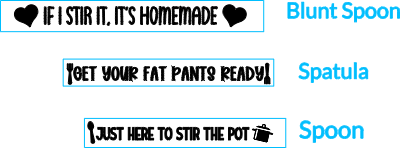

Laser-Engraved IKEA RÖRT Utensil Set (Beech Wood) - Sassy Chef

Information

Create a functional, gift-quality engraved utensil set that would actually be used, not just displayed — with clean, legible text on curved beech handles and consistent placement across three different utensil shapes.

This was a real-world project with no duplicate test stock, mixed utensil profiles, and natural wood variation — so repeatability and restraint mattered more than pushing contrast.

Instruction

Step1: Cut/Score/Engrave Custom Jig

*This jig can be adjusted to fit your spoons, the measurements can be changed or eliminated, the important piece is that the width of the slot cut out is no more than your spoon width +2mm(ish) as you don't want too much wiggle room and you can see the score marks to align the spoon left to right and at the center of the slot. This is a simple, quick, jig to create, but requires that your spoons are the same or similar in handle width. You can also adjust the overall size to utilize scrap or whatever you have around, omit the engraved guidance etc. I would recommend the use of standoffs if you have them.

Because the utensils were similar but not identical, I designed a custom alignment jig instead of trying to eyeball placement.

Jig features:

Single horizontal handle slot (22.5 mm wide) to lock rotation

Visual alignment only (no mechanical stops)

Engraved millimeter tick marks referenced from the handle end (most uniform feature)

Engraved baseline + centerline

Oriented so engraving ran with the grain (left → right)

This allowed precise placement for:

Spoon: 76 mm from handle end

Spatula: 102 mm

Scooped spatula: 127 mm (+ visual adjustment)

The jig eliminated rotation drift and made mixed utensil shapes easy to align calmly.

Step2: Engraving the Spoons

This project started as a functional gift, not a display piece. The goal was to create a set of engraved wooden utensils that would actually be used in a real kitchen, so durability, legibility, and placement mattered more than decorative detail.

I chose IKEA RÖRT beech utensils because they’re affordable, consistent in quality, and food-safe — but the set included three different shapes (spoon, spatula, and scooped spatula), which immediately ruled out eyeballing placement or using a one-size-fits-all approach.

Before engraving, I:

Lightly sanded the front handle area on each utensil to remove the factory finish where the engraving would go.

Evaluated grain direction and chose to engrave with the grain (left to right) for smoother, more uniform results.

Measured from the handle end, which was the most consistent feature across all three utensils, rather than from the head (which varied by shape).

Because the utensils were similar but not identical, I designed a custom alignment jig from 3mm basswood. Instead of using fixed stops, the jig uses:

A snug horizontal handle slot to prevent rotation

Engraved millimeter tick marks for visual positioning

A baseline and centerline engraved on the jig for consistent text alignment

This allowed me to place each utensil precisely while still adjusting visually for small differences in shape.

During testing, I discovered that thick paper masking caused light, broken engraving on beech wood when using a diode laser. After removing the mask, the engraving immediately became clearer and more consistent. From that point on, all utensils were engraved unmasked, using conservative settings to preserve clean edges and readability.

Once the jig and settings were dialed in, engraving the remaining utensils was straightforward and repeatable. Final finishing will be done with a food-safe cutting board oil after engraving.

This project reinforced that for real-world pieces, alignment and material understanding matter more than chasing maximum contrast, and that simple jigs with visual references can solve a lot of problems calmly.

Step3: Project Take-Aways

This project was a good reminder that real materials don’t behave like test scraps — and that’s not a bad thing. Working with curved beech handles, mixed utensil shapes, and natural wood variation pushed me to slow down, pay attention to alignment, and make decisions based on usability rather than perfection.

The biggest takeaway was that simple solutions often work best. A straightforward jig with visual reference marks solved more problems than complex stops or aggressive settings ever could. Likewise, removing masking on beech wood dramatically improved engraving clarity — something I wouldn’t have learned without testing on actual pieces.

In the end, the set feels cohesive without being uniform, functional without being fragile, and intentionally handmade. If you’re engraving wooden utensils for real use, focus on placement, grain direction, and restraint with power — the material will do the rest.

Thanks for following along, and I hope this helps someone else feel more confident tackling a “no test stock” project.

![[US Only for xTool S1] xTool Fire Safety Set: Auto Fire Detection, Fire Extinguishing](https://image-res.xtool.com/resource/xtool/community/accessories/20231018-183509.webp)