Report

![[Laser welding / cleaning] Laser Cut Modern Black Wooden Candle Holder with Glass Insert](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0000e835-131c-4277-af6c-1cb85ab3d1ce.jpg?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser welding / cleaning] Laser Cut Modern Black Wooden Candle Holder with Glass Insert](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0000e835-131c-4277-af6c-1cb85ab3d1ce.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser welding / cleaning] Laser Cut Modern Black Wooden Candle Holder with Glass Insert](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/c2a80379-a2d6-499e-abd3-f32b742d5bcb.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

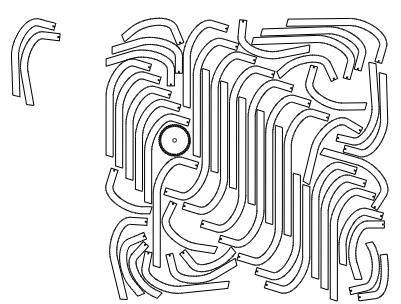

Curved Wave Lamp - Parametric Model generation

Curved Wave Lamp

.xcs

Application scenario

Laser welding / cleaning

Machine & module

xTool MetalFab Laser Welder

1200WCompatibles · 1

Material used

5/64"(2mm,Ga.14) ASTM-A36 Carbon Steel

8

124

Information

The Curved Wave Candle Lamp is a sculptural ambient lighting piece designed to create warmth, movement, and atmosphere. Its flowing, wave-like profile is formed from a series of precisely cut vertical slats that arc gracefully around a central candle, producing a striking sense of depth and motion from every angle.

When illuminated, the lamp casts soft, rhythmic shadows that ripple across surrounding surfaces, mimicking the gentle movement of waves or folded fabric. The layered construction allows the candlelight to diffuse naturally, creating a calm, inviting glow without harsh glare.

Designed to house a standard pillar or LED candle, the open base and elevated inner chamber ensure safe airflow while keeping the flame visually centred. The curved silhouette gives the lamp a modern, organic aesthetic that suits contemporary, minimalist, and natural interior styles alike.

This piece works beautifully as:

A statement centrepiece on a table or shelf

A mood light for living spaces or bedrooms

An accent feature for evening entertaining

Designed using Atomm's Parametric Model Maker!

Instruction

1

Step1: Project Guide

Couldn't quite fit all pieces on one cut in the MetalFab, sorry.

Cut all pieces out, clean up any edges that need cleaning, I used a wire wheel to smooth up the edges.

Arrange pieces from largest to smallest to allow correct assembly.

I slotted each piece into the centre cog like piece and then tac welded each piece as I went.

Once all pieces are in and tac welded, turn upside down, I found resting on a cylindrical item and aligning each piece to complete a final weld worked best for me.

Finish the surface with a coat of paint, oil, powder coat or clear coat to prevent rusting.

Enjoy your product!!!

Comments