![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/3f8eaa53-f316-45a3-ac0b-35d957ce08f6.jpeg?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/3f8eaa53-f316-45a3-ac0b-35d957ce08f6.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/91f4221e-e98b-4c0c-a92c-d149ec1e910a.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/e76e1717-2c3f-404b-8286-4d9270a20519.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/f38f75e7-4d9e-4bd6-9036-b7598fab8ed4.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/450794aa-e216-42f5-8748-83c9a7fd91a7.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Wooden Gear-Shaped Knobs with Threaded Inserts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/5cdb778e-ba14-4c9a-ae7b-13f37f527d8c.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

Laser Cut Hardwood Knob with a Threaded Insert

Information

This handy wooden knob with a 1/4"-20 threaded insert has a variety of uses in a workshop. This workshop knob can be used for woodworking jigs, table saw fixtures or clamping parts together. The diameter of the knob measures a comfortable 2-1/4" outside diameter & includes risers at the bottom for greater ease of use in tight situations. Included are the parts to make a counterbore jig with a drill press. The counterbore will ensure the threaded insert sits flush with the top of the knob.

Instruction

Step1: Hardware Used

Qty 1 - Tee Nut, ¼"-20, Fastenal #1137964 or equivalent

Qty 2 - 5/16" Flat Washers

Qty 1 - 5/16"-18 Hex Nut

Qty 1 - 5/16"-18 Hex Bolt

Notes: The Tee Nut will be permanently installed into the Knob. The bolt, washers & nut are used for gluing the knob parts together.

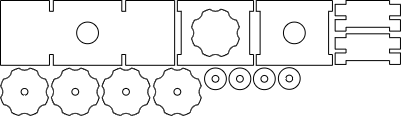

Step2: Laser Cut 4.5mm Thick Plywood Parts

Step3: Glue Up Knob Parts using hardware (except Tee Nut)

Using a good quality wood glue, apply glue between each wood surface & stack the assembled parts as shown. Tighten the nut securely. Wipe out any excess glued that has squeezed out. Allow to dry for 2-4 hours. Remove the nut, bolt & washers leaving only the glued up knob.

Step4: Glue Up Counterbore Drilling Jig

Using CA glue (or wood glue or a combination of both), assembled the parts of the drill counterbore jig as shown.

Step5: Add a 3/4" Dia Counterbore to top of glued knob

Using a drill press & a ¾" diameter Forstner drill bit, clamp & align the jig to a drill press table. Insert the glued knob into the jig. Drill a ¾" diameter counterbore into the top of the knob at a depth of 1/16". Remove the knob from the jig. Repeat if you are making multiple knobs.

Step6: Add threaded insert (Tee Nut) into knob at counterbore

Place a ¼"-20 Threaded Insert (a.k.a. Tee Nut) into the end with the counterbore. Hammer the threaded insert until it is flush with the top of the knob. Add 3 coats of clear acrylic finish. Presto! You're done!