![[Blade cut,Laser cut and engrave] Laser Cut Wooden Christmas Tree Ornament with Star Cutouts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/8224e182-6302-4f55-81a0-b07016141df8.jpg?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Blade cut,Laser cut and engrave] Laser Cut Wooden Christmas Tree Ornament with Star Cutouts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/8224e182-6302-4f55-81a0-b07016141df8.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Blade cut,Laser cut and engrave] Laser Cut Wooden Christmas Tree Ornament with Star Cutouts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/dad60837-0a95-458d-9fbc-71cec0d3b287.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Blade cut,Laser cut and engrave] Laser Cut Wooden Christmas Tree Ornament with Star Cutouts](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/2deee24a-1e63-4052-8ded-5def42a3f6c4.jpeg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

Laser Cold Processing: 3mm/8mm Wooden Christmas Tree Ornament

Information

🎄✨ Laser cold processing in action ✨🎄

This project is made using UV laser cold processing on 3 mm and 8 mm wood.

The result is a clean, precise cut with no burn marks on the surface or edges, preserving the natural texture of the wood 🌿

Perfect for holiday décor or Christmas gifts 🎁💡

Instruction

Step1: Before Starting

Hi guys! Wishing everyone a Merry Christmas in advance! 🎄✨

After working with glass inner engraving for a while, I started to get curious about how UV processing would perform on more common materials 😄

So today, I used the F2 Ultra UV to try cold processing for cutting.

I prepared 3 mm and 8 mm basswood plywood to see how thick the wood could be cut through.

Besides the material, you’ll also need a cuttable design—you’re very welcome to test it with the Christmas tree pattern I designed 😊🎄

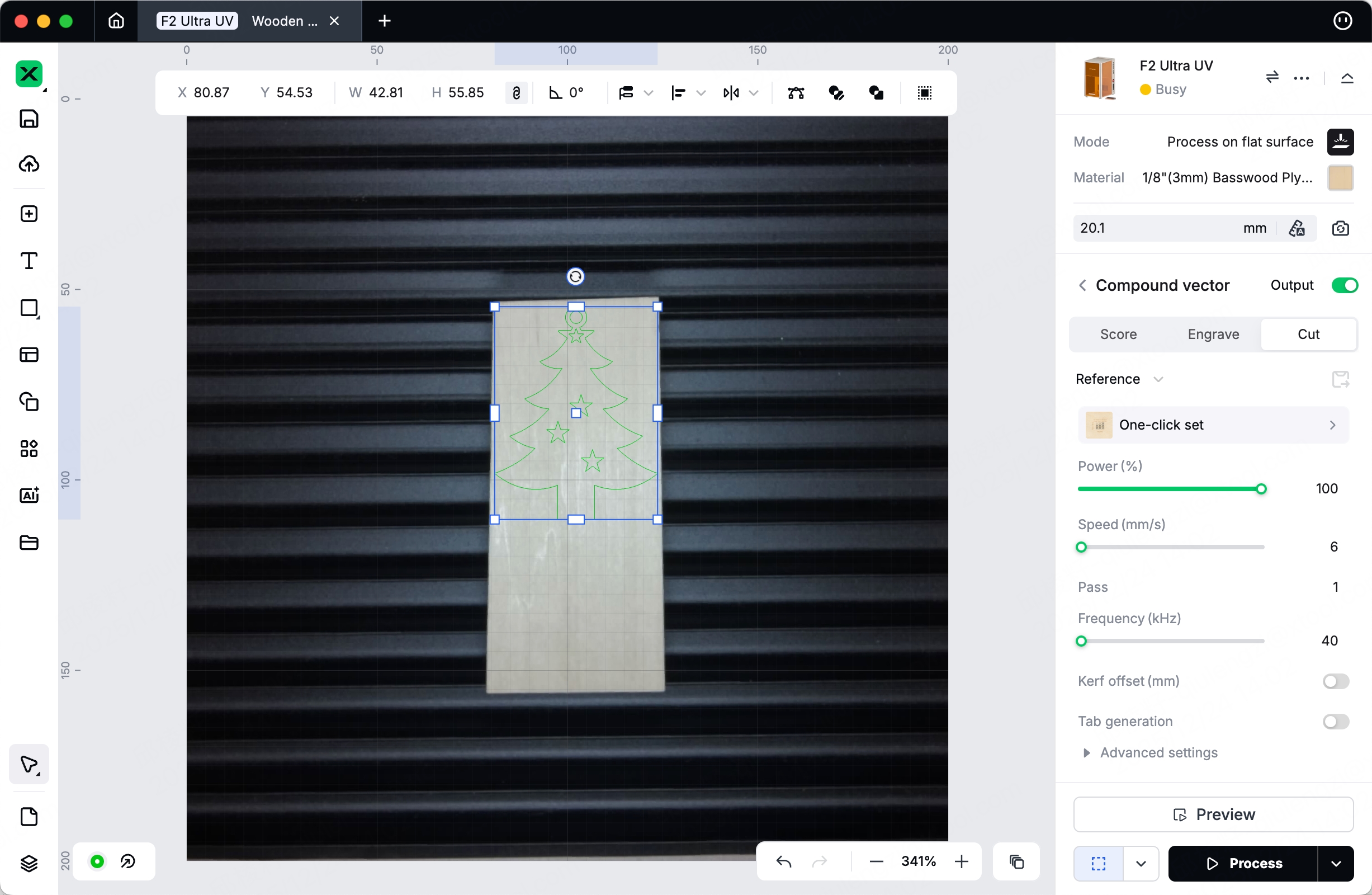

Step2: For 3mm

Processing 3 mm wood is absolutely no challenge for UV lasers.

The odor during cutting is also much lighter compared to fiber lasers and CO₂ lasers.

With just one pass, the piece can be cut cleanly, resulting in a “perfect” Christmas tree with no burn marks on the edges.

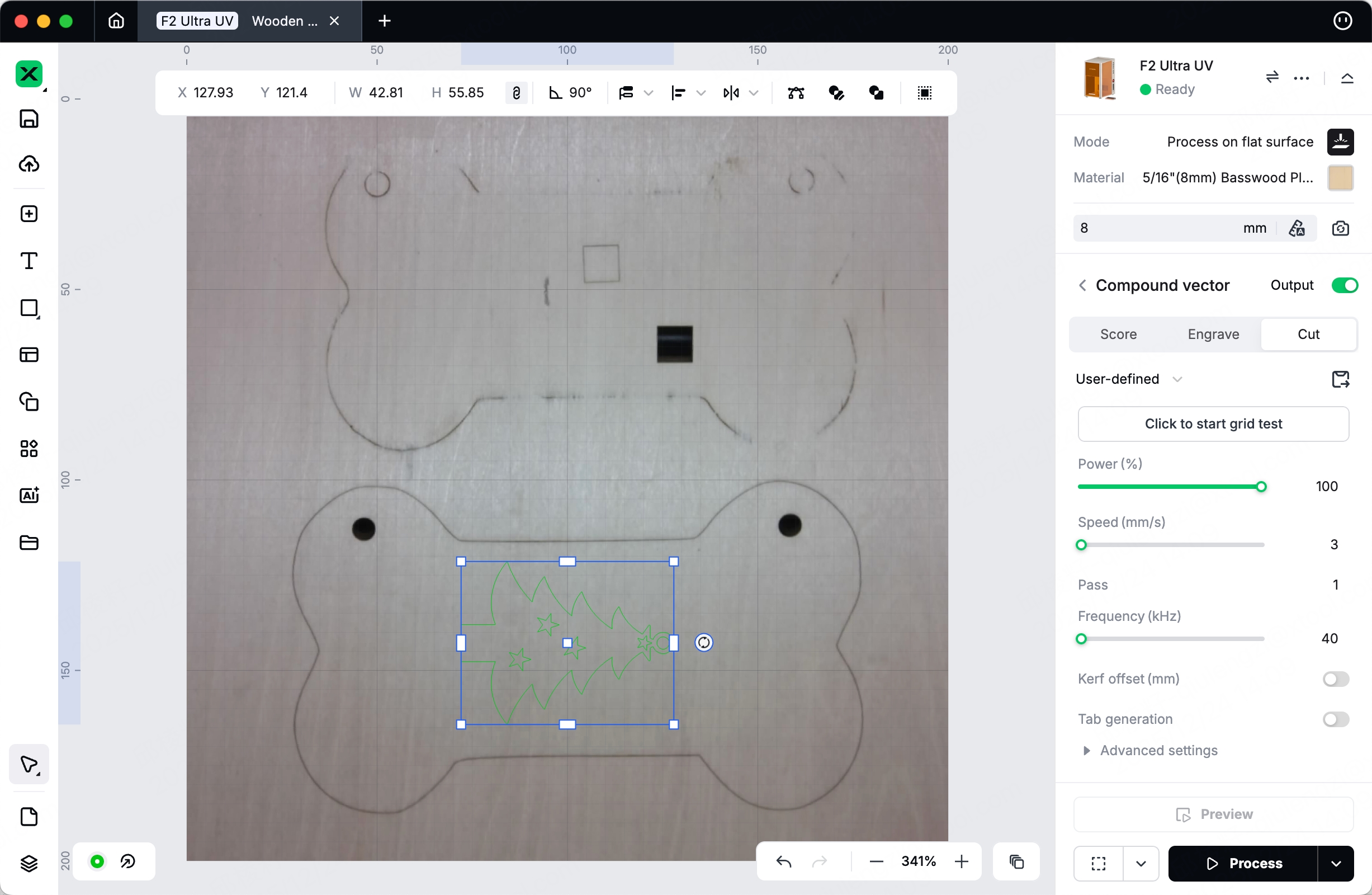

Step3: For 8mm

This was my first try with 8 mm basswood plywood, and I wasn’t fully confident about the settings, so I only slightly reduced the speed from 6 to 3.

As you can see in the video, the first pass left engraved marks on the thick board but did not cut all the way through. Without moving the material, I immediately started a second pass.

The second cut went relatively smoothly, but compared to the 3 mm board, the edges were clearly not as clean due to the repeated processing. For wood at this thickness, I’ll likely need to explore better parameter settings.

If you have a better solution or tips, feel free to leave a comment—let’s learn and improve together! 😊