Report

![[Laser cut and engrave] Laser Cut Coordinates Wall Art Sign with Heart Symbol](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/e178f2a5-35ff-47a2-928d-3eb62d835a11.png?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Coordinates Wall Art Sign with Heart Symbol](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/e178f2a5-35ff-47a2-928d-3eb62d835a11.png?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Coordinates Wall Art Sign with Heart Symbol](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/279b2c8f-c360-4a3c-9524-eb62ee943b7b.png?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Coordinates Wall Art Sign with Heart Symbol](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/a1a5365f-32ec-4770-892f-3f4023f5bc35.png?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Coordinates Wall Art Sign with Heart Symbol](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/c7b0bca0-6bea-47c6-b768-01b14588f983.png?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Laser Cut Coordinates Wall Art Sign with Heart Symbol](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/c922c707-ef73-4de2-97b9-fe4a22a076f3.png?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

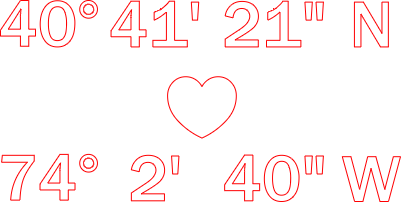

3D Custom Coordinates Sign

Custom Coordinates Sign

.xcs

Application scenario

Laser processing

Machine & module

xTool P2S

55WCompatibles · 2

Material used

1/2"(12mm) Black Walnut Plywood

1/2"(12mm) White Acrylic

1/8"(3mm) Red Acrylic

1/2"(12mm) Black Acrylic

8

70

Information

Every love story has a setting. Whether it's the place we met, the spot where we got engaged, or the address of our first home, immortalize that special location with this modern, handcrafted sign.

Unlike standard printed signs, this laser-cut acrylic is here to create a stunning 3D raised effect. The sharp black numbers pop against the rustic white wood, creating a premium look that adds depth and texture to any gallery wall.

Instruction

1

Step1

Software Setup Import Design:

- Open xTool Studio (XCS).

- Click Image -> Import and select the design you download from Atomm

- Assign Settings as per xTool recommendation

- Note: Always run a small 1-inch test circle first. If the edges are gummy, increase speed slightly. If it doesn't cut through, decrease speed.

- Masking: Ensure the acrylic is masked. Most cast acrylic comes with paper masking. Leave it on! If you are cutting mirrored gold, the grey back is usually not masked, so apply masking tape to the back to prevent scorch marks.

2

Step2

Machine Setup (xTool P2)

- Slats vs. Honeycomb:

- For acrylic, slats (the triangular bars) are often better than honeycomb because they have less surface area touching the back of the material, reducing "flashback" (grid marks burned onto the material).

- For acrylic, slats (the triangular bars) are often better than honeycomb because they have less surface area touching the back of the material, reducing "flashback" (grid marks burned onto the material).

- Focus:

- Place your material inside.

- In XCS, look for the Distance setting. Click the Auto-measure icon (the ruler) to let the P2 automatically measure the thickness/distance of the material.

- Place your material inside.

- Air Assist:

- Acrylic Trick: Unlike wood, you want LOW air assist for acrylic. High air cools the cut too fast and makes the edges frosty/white. Low air allows the laser to melt the edge slightly, giving you that crystal-clear, polished "flame polished" look.

- Acrylic Trick: Unlike wood, you want LOW air assist for acrylic. High air cools the cut too fast and makes the edges frosty/white. Low air allows the laser to melt the edge slightly, giving you that crystal-clear, polished "flame polished" look.

3

Step3

The Cut

- Framing: Click Process Framing to ensure your design fits on the scrap.

- Start: Close the lid and press the button.

- Watch It: Never leave the laser unattended, especially with acrylic (it is flammable).

4

Step4

Post-Processing

- Cool Down: Let the pieces sit for a minute or two. Acrylic is soft when hot; lifting them too early can warp the long thin stick of the stirrer.

- Unmasking: Peel off the paper masking.

- Cleaning: If there is any sticky residue, wipe it with a microfiber cloth and a little isopropyl alcohol (or plastic cleaner). Warning: Don't use 100% alcohol on extruded acrylic as it can crack it; cast acrylic is usually safer.

Comments