![[Laser cut and engrave] Coffee Mug, Coaster and Pod Organizer](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0b8ee2cf-2760-4635-b47f-388f30a23fc9.jpg?x-oss-process=image/resize,w_1200,h_900,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Coffee Mug, Coaster and Pod Organizer](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/0b8ee2cf-2760-4635-b47f-388f30a23fc9.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Coffee Mug, Coaster and Pod Organizer](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/44772dad-70f2-475d-97b9-a1a6d670fc12.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Coffee Mug, Coaster and Pod Organizer](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/e7316a76-3992-4085-a384-479b0236851e.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Coffee Mug, Coaster and Pod Organizer](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/09b3d8f8-44a1-411d-a6ad-23b768efa0a1.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

![[Laser cut and engrave] Coffee Mug, Coaster and Pod Organizer](https://storage-us.atomm.com/resource/xtool/community/attachment/xtool-community/c9bde2d3-9f73-4dae-969b-048abcb8927c.jpg?x-oss-process=image/resize,w_200,h_150,limit_0/interlace,1/format,webp/auto-orient,1)

Coffee Mug, Coaster and Pod Organizer

Information

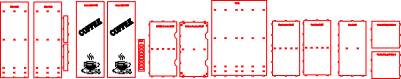

Coffee station organizer that stores four mugs, four coasters, and up to eight pods.

Instruction

Step1

The project took me six sheets of 1/8" (3MM) Walnut plywood. (I also did a mockup using the same amount of Basswood). It took two hours from start of first cut to final assembly.

I cut all pieces and dry fit prior to using CA Glue for final assembly.

The pieces are labeled in the project file. All the individual pieces are grouped to help keep the integrity of the tab slots. I would recommend moving the grouped pieces to the work canvas then ungrouping them to choose no output for the text labels. (Remember to regroup once the cuts are complete to move off the canvas). I am sure there is a proper way to do this step, but I do not know the step or command)

The “Outer Side Walls” text and graphic can be changed to your liking.

DO NOT glue the outer side walls on until you have done a dry fit.

The kerf settings I used made for a really tight fit…uncomfortably tight. I would recommend testing and using the setting that works best for your machine.

Dry fit the entire project as the pieces may need to be flipped or turned around to ensure proper alignment.

I used coaster cork on the mug cubbies (this is optional).

This is my first major project, I hope you all enjoy it.